- Your cart is empty Browse Shop

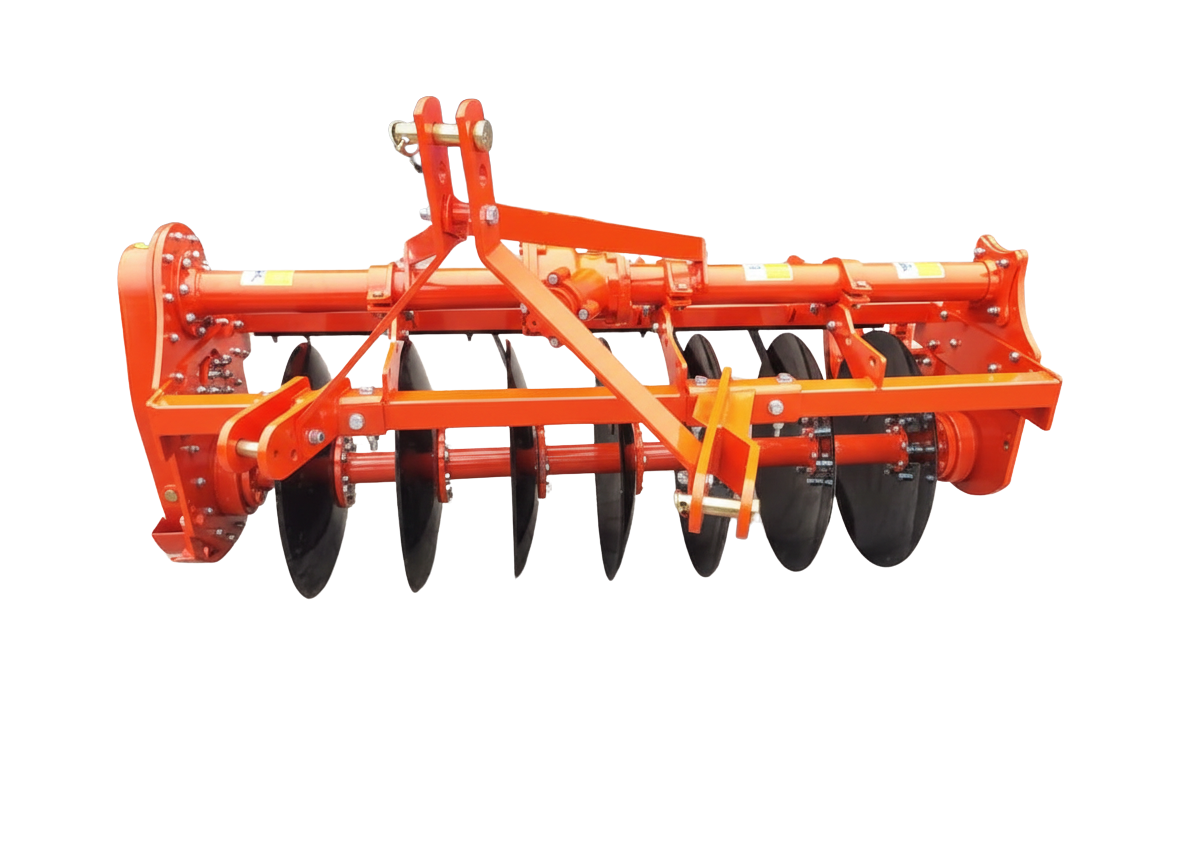

Why Your Disc Harrow Isn’t Cutting Straight

A disc harrow that fails to cut straight can reduce field efficiency, increase fuel consumption, and create uneven soil preparation. If your implement i

Common Causes

1. Uneven Disc Wear

Worn-out or unevenly sized discs can cause imbalance, leading to improper soil penetration and directional drift.

2. Incorrect Gang Angle Adjustment

Improper gang angle settings affect soil resistance. If the angles are not aligned evenly on both sides, the harrow may pull to one direction.

3. Frame Misalignment

A bent or twisted frame can disturb weight distribution, preventing uniform cutting depth.

4. Improper Tractor Hitch Setup

Incorrect three-point hitch leveling is one of the most common reasons. If the implement is not properly centered or leveled, it won’t track straight.

5. Uneven Soil Conditions

Hard patches, stones, or variable soil moisture can also influence cutting consistency.

Your time is limited, so don’t waste it living someone else’s life. Don’t be trapped by dogma – which is living with the results

John Mehedii

How to Fix It

- Inspect frame alignment

- Check and replace worn discs

- Ensure equal gang angle adjustment

- Level the three-point hitch properly

- Maintain proper operating speed

At Krittvo International, precision-engineered disc harrow components are designed for balance, durability, and consistent field performance under real agricultural conditions.